BNL Home Improvements specializes in the consultation and insulation of a variety of flat roofing systems for your home.

BNL Home Improvements specializes in the consultation and insulation of a variety of flat roofing systems for your home.Every job, client and budget requires a different solution. We offer various types of flat roofing options but the three below are our primary suggestions.

The trade referred to as waterproofing encompasses a wide variety of specialty applications of different waterproof products. Ultimately, BNL Home Improvements 's commercial waterproofing services include the professional installation of waterproofing materials that keeps water out .

Whether waterproofing a new or existing structure, regardless if the service need is preventative or reactive,BNL Home Improvements 's comprehensive waterproofing services keep the water out while giving you a more green roofing solution. .

Review the tabs below and if you have any questions feel free to call us at (908) 343-3590

EPDM has been in use on roofs in the USA since the 1960's and is one of the most common types of low-slope roofing materials. This is because it is relatively inexpensive, simple to install, and fairly clean to work with when compared to conventional built-up roofs. There aren't the odors and fumes that accompany built-up roofs which appeals to many property owners and managers.

EPDM is a rubber material whose principal components consist of the compounds ethylene and propylene. A flexible rubber matrix forms when a small amount of diene is added to the mix. EPDM is available reinforced or unreinforced with both commonly used; it's also available in either a cured (vulcanized) or uncured (non-vulcanized) state. Vulcanized EPDM is the most common with non-vulcanized often used for flashing purposes.

EPDM membrane thickness ranges from thirty mils (0.030" - which I've never seen used for roofing) to one-hundred mils (0.100") with the most common thicknesses being forty-five mils (0.045") and sixty mils (0.060"). There are three standard application procedures: (1) fully-adhered; (2) mechanically-fastened; (3) loose-laid. Fully-adhered EPDM uses water-based or solvent-based adhesives to adhere the rubber to the substrate. Mechanically-fastened EPDM is attached by manufacturer-approved mechanical means to the substrate, and loose-laid membranes are secured only at the perimeters and any penetrations, then a ballast of round river rock or concrete pavers is used to hold the materials in place. River rock is usually installed at a rate of 1000 - 1200 pounds per roof square (100 square feet) and the pavers generally weigh approximately 20 pounds per square foot. Structural integrity is important with loose-laid ballasted roof systems. The seams of all systems are sealed using either an adhesive or a splice tape. Splice tapes have tested with a higher tear-strength.

How Long Do They Last?

As with most roofs, EPDM rubber roofs have varying lifespans that depend on numerous criteria. These include environmental conditions such as what type of building (factory or church), how much foot traffic the roof gets, how much water remains on the roof after a rain, and how long it take that water to evaporate. Not to mention geographical location. Roofs in mild climates will outlast roofs in harsher climates. Of course, one of the most important factors in a roof's life expectancy is quality of workmanship. If the roof is not properly installed, then its lifespan will be shortened.

Properly install EPDM rubber roofs should last between 12 and 25 years.

Here's a brief breakdown base on observations over the past 15 years:

- 45 Mil Ballasted EPDM Rubber properly installed that drains well - 12 years

- 45 Mil Mechanically Attached roof properly installed that drains well - 12 years

- 45 Mil Adhered roof properly installed that drains well - 12+ years

- 60 Mil Ballasted EPDM Rubber properly installed that drains well - 12+ years

- 60 Mil Mechanically Attached roof properly installed that drains well - 15 years

- 60 Mil Adhered roof properly installed that drains well - 15+ years

- 80+ Mil Mechanically Attached roof properly installed that drains well - 20+ years

- 80+ Mil Adhered roof properly installed that drains well - 20+ years

- 80+ Mil Fleeceback Adhered roof properly installed that drains well - 25+ years

TPO Thermoplastic Polyolefin - Rubber

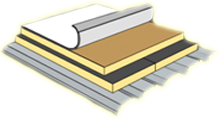

Fully Adhered TPO

The Adhered TPO System is ideal for many different types of buildings. It is especially good for roofs not designed for the weight of ballast or that have many roof penetrations and can be installed on almost any roof deck.

Sheets of insulation are laid out on the decking and fastened according to the system specifications. TPO sheets are then adhered to the insulation. Adjoining sheets are overlapped and heat-welded using specialized welding equipment.

System Benefits

- Low Maintenance

- Reflective Roof System

- Durable

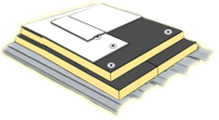

Mechanically Fastened TPO

Mechanically Attached Roofing Systems are ideal for many different types of buildings and can be an economical solution where conditions are suitable. Sheets of Insulation are laid out on the decking and fastened according to the system specifications. The insulation is then covered with sheets of TPO and plates and fasteners are installed in the membrane seam. Adjoining panels are overlapped and heat welded using specialized welding equipment.

Sheets of insulation are laid out on the roof system and then either adhered, with bonding adhesive, or mechanically fastened with insulation plates and fasteners to the roof decking. Sheets of TPO membrane are then laid out to cover the insulation. Adjoining sheets are then overlapped. The bottom layer of membrane is mechanically fastened to the roof decking and the top layer of membrane is then heat welded to the bottom of the TPO, creating a solid sheet of membrane. The perimeter of the roof and all penetrations are then flashed according to the technical specifications.

System Benefits

- Economical White Roof System

- Reflective Roof System

- Lightweight

Liquid roof systems are tough, cold applied membranes giving exceptional durability and lasting peace of mind.

Liquid roof systems are tough, cold applied membranes giving exceptional durability and lasting peace of mind.These systems provide a lasting barrier to water penetration and are highly resistant to sunlight.

These systems are easily applied to all types of roof structures. The liquid composition allows complex shapes to be easily and seamlessly waterproofed without removal, in many cases, to the existing substrate, meaning less disruption during application.

This type of roofing system also allows your business to take advantage of being more green.

Cool roof technologies will help reduce your carbon footprint and help cut your cooling bills.

These technologies can be membranes or roller applied roof coatings.

Ask BNL Home Improvements for additional brand or color options.